engineering

Engineering Excellence Across Multiple Disciplines

Samuel, Inc. is a true multi-discipline company with highly experienced professional engineers and designers.

Chemical and Metallurgical Process, Mechanical, Civil/Structural, Electrical, and Automation/Instrumentation engineers and designers easily work together to ensure the optimal design solutions are provided on time and within budget.

PROCESS engineering

Samuel’s process engineers are capable of forming PFDs/P&IDs, modeling & simulation, mass energy balances, equipment and line sizing, hydraulics, HAZOP/process hazard analysis’ and much more.

PIPING engineering

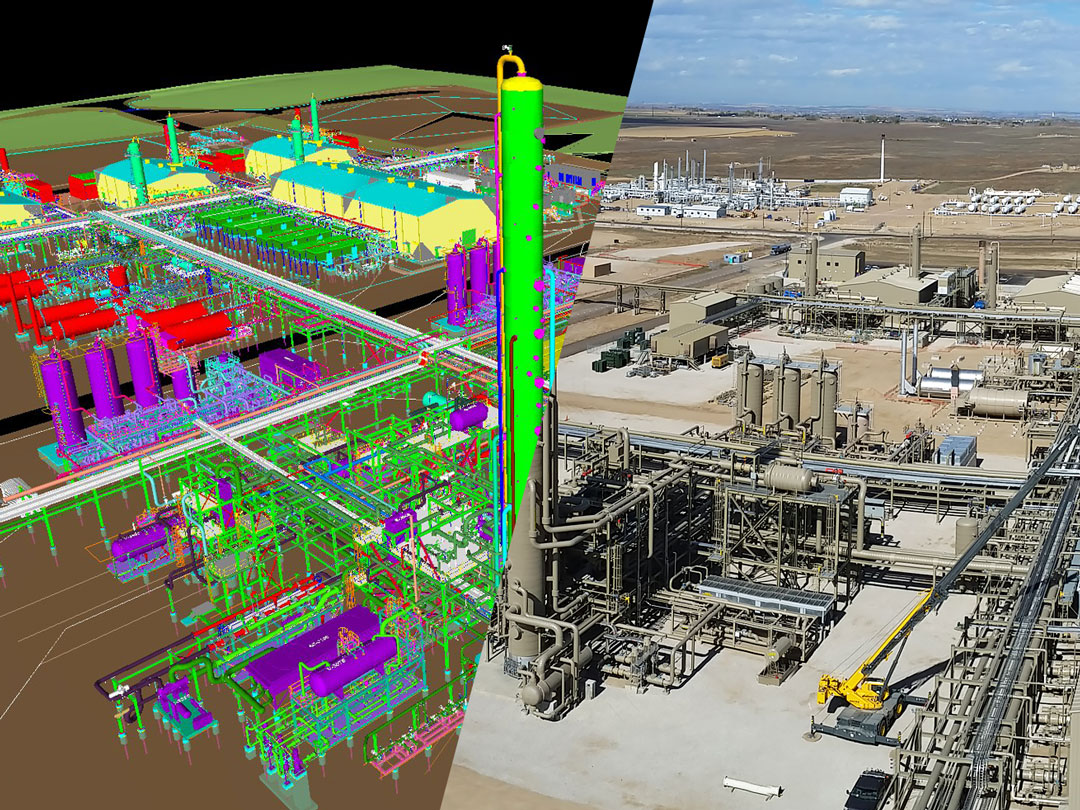

Process flor diagrams, piping and instrumentation diagram development, full ortho and isometric drawing packages, 3D plant design modeling, modular & skid design, project walk downs for as-builts, piping retrofit & optimization

PLANT LAYOUT

Process plant general arrangements, pipe rack layout, material handling systems layout, plant roads & infrastructure layouts, mechanical systems, 3-D CAD design, equipment modeling & layout, interactive design review

Structural engineering

Structural steel, plate work, structural concrete, masonry, wood, fiber-reinforced polymer (FRP), modular structures, foundation types, and building types The team utilizes 3D software to integrate mechanical and piping models

Mechanical engineering

Mechanical systems engineering & design, pump & rotating equipment analysis, trade-off studies & root cause analysis, plant debottlenecking, start-up and commissioning, pipe stress analysis, equipment specification

Electrical engineering

Power system analysis, equipment specification, evaluation & selection, physical plant design, control & schematic design, power transmission & distribution design, substations, emergency generator designs, lighting

instrumentation

P&ID and process condition review for proper instrument and valve selection, sizing, specifications, datasheets, field set up and calibration. SE’s instrumentation group ensures measurement & control devices are correct.

automation

Definition of functional requirements, design of networking architecture, throughput & security concerns, coordination of communications, panel design, programming, pre-install testing, control panel design

civil engineering

Site grading & design, site earthwork balancing, roadway design, 3-D facilities modeling & visualization, drainage planning, erosion control, subsurface utility planning, drawing preparation

Oil & Gas Process

Core Capabilities

- PFDs and P&IDs

- Modeling and simulation

- Mass and energy balances

- Equipment and line sizing

- Hydraulics

- Vendor packaged equipment reviews

- Process troubleshooting and optimization

- Equipment replacement and upgrade

- Facility upgrades, expansions and de-bottlenecking

- HAZOP / process hazard analysis

- Relief and flare system analysis, design and documentation

- ESD/cause and effect diagram audit, analysis and update

- Equipment documentation / data sheet audits

- Operating procedures

Specialized Software

Process Metallurgy

Core Capabilities

- Test work planning and management

- Metallurgy

- Process flow sheet development

- Unit operation specification

- Process material specification

- Reagent specification and handling

- Process design criteria

- Water, mass and energy balances

- Preliminary economic assessment

- Feasibility studies

- Plant de-bottlenecking

Specialized Software

Plant Layout & General Arrangement

SE’s plant layout group provides designs ranging from conceptual facilities to detailed engineered plants. With 3-dimensional CAD software, we provide models and drawings for costing, design or project development presentations.

Core Capabilities

- Processing Plant General Arrangements

- Pipe Rack Layout

- Material Handling Systems Layout

- Plant Roads and Infrastructure Layout

- Mechanical Systems

- 3-Dimensional CAD Design / Integration

- Equipment Modeling and Layout

- Interactive Design Review Facilitation

Specialized Software

Civil Engineering

The civil engineering group at Samuel Engineering, Inc. (SE) provides complete design packages for clients in all sectors of engineering. Projects include heavy industrial development for mining and oil & gas facilities, commercial development for solar farms & convenience facilities, government projects and power generation.

Core Capabilities

- Site Grading and Design

- Site Earthwork Balancing

- Roadway Design

- 3-Dimensional Facilities Modeling and visualization

- Drainage Planning and Design

- Erosion Control Best Management Practices

- Subsurface Utilility Planning and Design

- Efficient, Organized and Accurate Drawing Preparation

- Cut and Fill Quantity Take-offs

- Construction Support

Specialized Software

- Bentley – InRoads, Pondpack, StormCAD, Decartes

- AutoTurn

- Navisworks

- MicroStation & AutoCAD Platform

- Haestad Methods

Oil & Gas Mechanical Engineering

Core Capabilities

- Mechanical Systems Engineering and Design

- Pump and Rotating Equipment Analysis

- Trade-off Studies and Root Cause Analysis

- Plant Debottlenecking, Start-up and Commissioning

- Pipe Stress Analysis

- Equipment Specification, Evaluation and Selection

- Gas Compression

- Pumping

- Well Pad Design, Valve and Meter Stations

- Pressure Vessels and Piping Systems

- Crude Treating

- Heating and Separation

- Dehydration, Treating and Stabilization

- Pipelines

- Natural Gas Processing

- Storage

Mining Mechanical Engineering

Core Capabilities

- Mechanical Systems Engineering and Design

- Plant Equipment and Layout Analysis

- Trade-off Studies

- Plant Debottlenecking, Start-up and Commissioning

- Equipment Specification, Evaluation and Selection

- Crushing and Grinding

- Material Handling

- Dust Collection

- Dilute Slurry and Paste Pumping

- Solids / Liquid Separation

- Gravity, Magnetic, Flotation Separation

- Size Separation

- Solvent Extraction & Electrowinning

- Leaching – Autoclaves and CIL/CIP

- Reagent Handling and Mixing Systems

- Underground Infrastructure

Piping

SE’s piping team provides a variety of expertise in Mining, Oil and Gas (Upstream, Midstream and Downstream), and Power industries. We provide solutions from conceptual stages through start-up and commissioning.

Core Capabilities

- Process Flow Diagrams

- Piping and Instrumentation Diagram Development

- Full Ortho and Isometric Drawing Packages

- 3D Plant Design Modeling and Project Review

- Modular and Skid design

- Project Walk Downs for As-builts, Expansion, Compliance

- Piping Retrofit and Optimization

Specialized Software

Structural Engineering

The Structural team at Samuel Engineering, Inc. (SE) has in-depth experience in all stages of design and construction for heavy industrial applications. With a focus on constructability, our team provides solutions that minimize construction duration and downtime. The team utilizes intelligent 3D software to integrate mechanical and piping models which allows SE to deliver solutions that are easy to fabricate and construct.

Core Capabilities

- Design and Analysis of:

- Structural Steel -Buildings, Skids, Pipe Bridges, Platforms and Equipment Support Platforms.

- Plate Work – Tanks, Bins, Hoppers, Launders, Chutes, Storage Silos and Stacks.

- Structural Concrete – Columns and Beams, Frames, Equipment Supports and Containments.

- Masonry – CMU and Brick Walls, Retaining Walls and Pilasters.

- Wood – American Wood Frame, Laminated Lumber, Trusses, Columns and Beams.

- Fiber-Reinforced Polymer (FRP) Access Platforms, Stairs and Supports.

- Modular Structures, Skidded Equipment Supports and Skidded Building Supports.

- Foundations for Equipment, Buildings, etc.

- Buildings – Custom Designed, Pre-Engineered and Modular.

- Design Codes/Code Review

- ACI, AISC, ASCE 7, API, IBC, SNIPs, Canadian

- Seismic Codes

- AISC, ASCE 7, Guatemala, SNIPs, Armenian, SDC=D,E (High Seismicity)

Specialized Software

Electrical Engineering

Samuel Engineering Inc.’s (SE) electrical group is a true Center of Excellence! Whether defining loads, specifying equipment, modeling using 2D & 3D intelligent CAD software, developing design drawings, overseeing factory acceptance testing or providing on-site commissioning and start-up support, our team will work with you to complete an entire project or a very specialized study.

Core Capabilities

- Power System Analysis (Short Circuit, Motor Starting, Protective Device Coordination, Load Flow, Power Factor Correction, Voltage Drop Calculations, Arc Flash Studies, etc.)

- Equipment Specification, Evaluation and Selection (Transformers, MCCs, VFDs, Motors, Switchgear, etc.)

- Physical Plant Design

- Control & Schematic Design

- Power Transmission & Distribution Design

- Substation Design

- Standby / Emergency Generator System Design

- Lighting, Grounding and Lightning Protection

- Complex Electrical System Studies

- Control Philosophy Development

- Plant Start-up and Commissioning

Specialized Software

Instrumentation

SE’s instrumentation group ensures the selection and specification of measurement and control devices are correct. Our engineers see this as being crucial to providing a successful working process and understand that items selected must be of the correct size, technology and material for the application under consideration.

Core Capabilities

- P&ID and process condition review for proper instrument and valve selection

- Sizing

- Specification

- Datasheets

- Field set-up and calibration

Automation

SE is experienced in all facets of the design of automation systems. We have expertise ranging from the definition of the concept and requirements, through the communications equipment and connections, to the programming and commissioning. Our team will work with you, either as part of a complete project team or as a “stand alone” automation project.

Core Capabilities

- Definition of functional requirements

- Design of networking architecture, including throughput and security concerns

- Fiber Optic and Switch Layout

- Defense in depth security approach

- Coordination of communications between Vendors

- Panel design

- Programming/Configuration

- Pre-installation testing

- On-site commissioning and testing

- Migrating obsolete control systems into newer platforms

- Control panel design

PLCs

- Rockwell ControlLogix

- Schneider Modicon

- Siemens

- GE

- SCADAPack

DCSs

- Emerson Delta V

- Honeywell PKS

- ABB 800xA

HMIs

- Rockwell FactoryTalk View

- Rockwell RSView

- Wonderware ArchestrA

- Wonderware InTouch

- GE iFIX

- Iconix

- ClearSCADA

- Ignition SCADA by Inductive Automation