Oil & Gas process

Core Capabilities

- PFDs and P&IDs

- Modeling and simulation

- Mass and energy balances

- Equipment and line sizing

- Hydraulics

- Vendor packaged equipment reviews

- Process troubleshooting and optimization

- Equipment replacement and upgrade

- Facility upgrades, expansions and de-bottlenecking

- HAZOP / process hazard analysis

- Relief and flare system analysis, design and documentation

- ESD/cause and effect diagram audit, analysis and update

- Equipment documentation / data sheet audits

- Operating procedures

Specialized Software

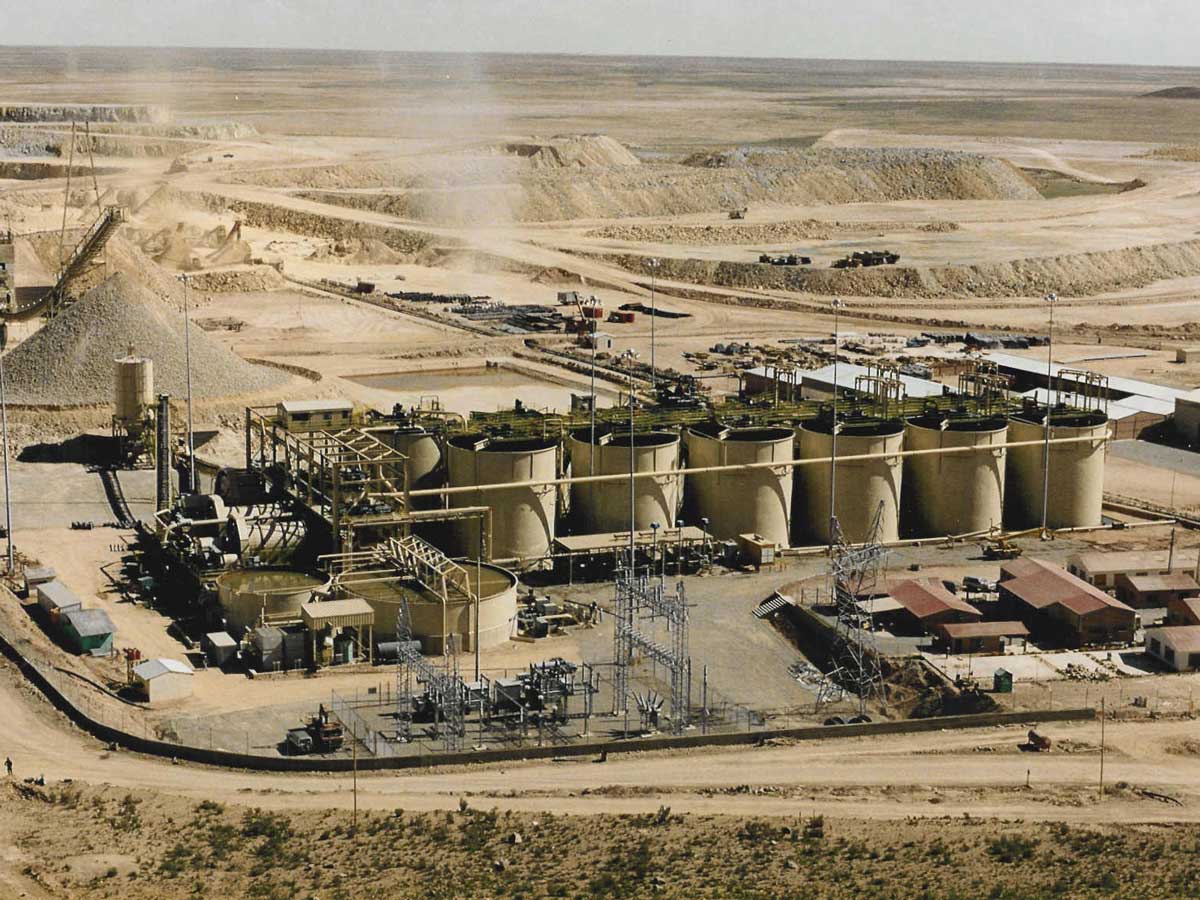

PROCESS METALLURGY

Core Capabilities

- Test work planning and management

- Metallurgy

- Process flow sheet development

- Unit operation specification

- Process material specification

- Reagent specification and handling

- Process design criteria

- Water, mass and energy balances

- Preliminary economic assessment

- Feasibility studies

- Plant de-bottlenecking

Specialized Software